Spacesaver Storage Solutions offers a system that helps you improve your ROI on your product.

This system offers indoor and greenhouse growers a safe, efficient and effective method to move any type of grow light, ventilation, heating or drying rack system. Our patent pending systems deliver feedback on when, how much, and by whom lights were moved. This solution provides deep insight into operations.

Features & Benefits

Lighting System

Features

Adjustable lighting allows movements as small as one millimeter to achieve ideal distance from canopy at all times

Works overhead and integrates with Multi-tier Grow systems

Works with new or retrofitted operations

Machine is aware of its location and can integrate into grow systems or ERP

One button system control, allows one technician to adjust to 72 or more grow lights at a time

Eliminates need for ladders to adjust and change all lights

Six safety features built into each machines

Food-grade grease in all components

We can cover more than 2100 square feet of canopy with one machine.

We can also custom design any size room for you.

Benefits

Keeping the right light on an indoor grown product reduces energy use, heat load, and increases grow efficiency

The system delivers clear ROI through increased production, energy reduction, labor reduction and heat load reduction

Light moving ‘event logging’ helps you achieve faster and more consistent harvest rates

Improves efficiency of operations by virtually eliminating employee time needed for moving lights

Reduces chance of lost time and workers compensation claims from ladder related injuries

Eases maintenance and cultivation tasks

Safety Features

Grow Safety Features

Each machine is equipped with six key safety features:

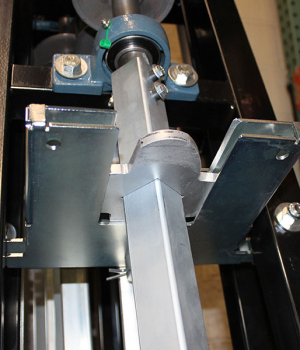

Electric Motor Brake: Positively locks load in place at any position. Engages automatically when power is removed.

Momentary Switches: Operator must be engaged with machine to operate. Releasing switch positively locks machine in place.

Free-fall Arrestor: In the unlikely case that motor and chain drive fail, arrestor positively stops load in inches

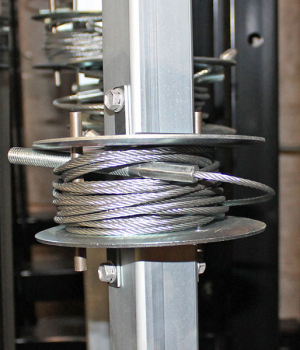

Lifting Cables: Made of high strength aircraft grade steel, cables are rated to 2,500 pounds each. Melting point is over 1,600 degrees Fahrenheit.

Safety Cables: ¼” aluminum cables are rated to 2,000 pounds each and back up lifting cables.

Upper Limits switches: Double fail safe upper limit prevents machine from overwinding and causing damage.

Payload Capacity: 850 pounds of active load per eight feet. Up to 72 feet per machine depending on load design.

Why Do Advanced Safety Features Matter?

You want a lift machine system that is guaranteed to pass muster with regulators and last a long time. We have dealt with regulators in multiple countries for the past 27 years and our machines are built to last.