Temperature-Controlled Storage for Cooler/Freezer Applications

Save energy in cold storage with temperature-controlled storage

A full cooler is a more efficient cooler, and we can help eliminate every cubic foot of wasted space in your cold storage facility with temperature-controlled storage . By compactly storing frozen items on the ActivRAC® Mobilized Storage System, you can:

- increase your facility’s capacity

- maintain 100% selectivity

- save on energy costs

The ActivRAC system not only saves on energy costs — it can also save on construction or rental costs. Web Industries found that by using an ActivRAC system they could store the same amount of material in a freezer half the size; read the case study here.

Constructing or renting new cold storage spaces isn’t your only option. A cost-effective alternative is rethinking your cold storage shelving and maximizing that pricey square footage in a whole new way.

Benefits

Movable Shelves

Are you struggling with limited freezer and cooler space in your warehouse? Do you find it challenging to store and manage your temperature-controlled products efficiently? Look no further! Our state-of-the-art systems feature carriage and rail technology that revolutionizes the way you utilize your storage area. With our mobile racking solutions, you can say goodbye to static aisles and unlock the full potential of your existing space without the need for costly expansions or leases.

Here are some remarkable benefits that our temperature-controlled storage systems offer:

Space-saving Brilliance:

With our mobile racking systems, every inch of your premium freezer and cooler space becomes usable. By eliminating static aisles, our shelving or racking moves effortlessly from side to side, enabling you to maximize storage capacity. This means you can store a larger quantity of products and goods without the hassle and expense of constructing or leasing a new warehouse.

Optimal Visibility for Enhanced Handling:

Our systems provide optimum visibility to items, making it easier to handle mixed-product pallets and smaller batches. By improving visibility, you can swiftly locate and retrieve the required items, saving valuable time and effort. The ease of handling translates to enhanced operational efficiency and streamlined workflows.

Energy Efficiency and Cost Reduction:

Through the utilization of heavy-duty mobile pallet racking, our systems enable you to create a densely packed cooler or freezer. This density reduces the space between pallets, resulting in lower costs per pallet and energy consumption. By optimizing the utilization of your temperature-controlled space, you can achieve significant cost savings while contributing to a greener environment.

Boosting Labor Productivity:

Imagine having 100% accessibility to all your products within a compacted space. Our systems make it possible. By eliminating long travel times and unnecessary touches, your workforce can efficiently navigate through the storage area, retrieving items with ease. The result? Increased labor productivity and reduced operational downtime.

Unlocking Value-added Activities:

With the additional space created by our mobile racking systems, you can now explore value-added services and operations. From repack operations and consolidations to customization and shorter shipping cycles, the possibilities are endless. Embrace efficiency and create new opportunities to add value to your operations while optimizing your inventory management.

Enhanced Control and Compliance:

Our mobile storage solutions offer improved selectivity, enabling better inventory control and regulatory compliance. With easy access to all your products, you can effectively monitor stock levels, implement quality control measures, and meet regulatory requirements without compromising efficiency.

Supporting Lean Processes:

Efficiency is the cornerstone of lean processes, and our systems perfectly align with this principle. The improved selectivity and accessibility created by our mobile pallet racking facilitate streamlined workflows, waste reduction, and overall process optimization. By embracing our innovative solutions, you can take your operations to the next level of efficiency.

In conclusion, our carriage and rail systems offer a transformative approach to temperature-controlled storage. By leveraging our mobile racking solutions, you can save space, reduce energy costs, improve labor productivity, unlock value-added activities, enhance control and compliance, and support lean processes. Say goodbye to wasted space and hello to a more efficient and profitable future. Contact us today to explore how our systems can revolutionize your storage operations!

Composite Manufacturer

Frozen Warehouse Storage

Composite materials allow aerospace manufacturers to build aircraft that are lighter, stronger, and more fuel efficient than their counterparts made of metal. That’s because composites consist of strong carbon fibers embedded in resin-like material, making them more resistant to corrosion and fatigue-related failure. But processing composites is a tricky process: heat causes the unfinished material to degrade, so the material must be kept at extremely cold temperatures until it is formed and finished for assembly.

When the composite materials aren’t being processed, they must be stored at -10 degrees Fahrenheit to prevent premature curing and extend shelf life.

After formatting, the products are refrozen and stored until they can be shipped to the end user, where they are used to manufacture composite aircraft and engine parts.

Craft Beer

“Craft beer is exploding.” This observation from an Operations Manager at a beer distribution company is great news for beer aficionados and beer distributors – but it’s not without its complications. Despite minimal growth in the mainstream beer market, the craft beer segment grew 17% in 2014. Although craft beer still only accounts for only 6.5% of the beer U.S. beer market, craft breweries account for 98% of the breweries.

More Kegs, More Problems

For beer distributors, the proliferation of unique microbrews means more market opportunities, but also means more products, space, and capital needed to accommodate them. Unfortunately, the distributor had a fixed amount of temperature-controlled storage space, and it became increasingly difficult to handle the influx of new product at the warehouse.

With overcrowded coolers, retrieving kegs became a frustrating ordeal. The 1500 square foot storage cooler was lined with racks of static shelving. Kegs were stacked one on top of the other on the shelves and on pallets in the center of the floor. Employees had to unload the cooler each morning just to get into the cooler and access to the kegs for distribution that day. The accessibility issue slowed operations and created an inefficient process that could slow deliveries. Unstacking and restocking the 165 pound kegs was not only inefficient, but also posed a possibility for injury. The distributor considered adding additional warehouse space, but doing so was capital-intensive and would require additional employees.

The increasing customer demand for a variety of craft beers, ciders, and other beverages can be a serious concern, especially when space is at a premium in your warehouse. Luckily, there’s an alternative to expanding or renovating your warehouse – mobile keg racks.

Here at Spacesaver, we’ve done some research on how you can properly manage those slow-moving SKUs for much-needed space, while at the same time freeing up critical and accessible space for fast-moving items that make up the majority of your profits.

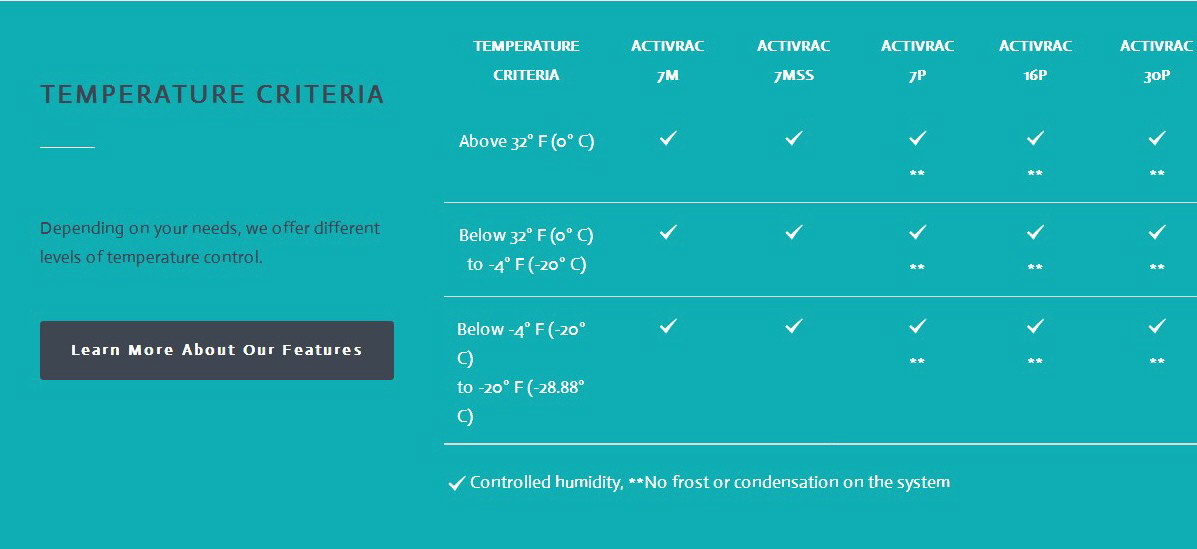

Global Pharmaceutical

Mobile racking isn’t just for food and beverage—a global pharmaceutical company was in the midst of expansion, and unfortunately, an expansion of the company didn’t quite translate into an expansion of storage space. Due to very temperature-specific storage needs, chemicals and tests related to particular projects were being stored all over the lab, and the lack of organization was slowing down progress. An ActivRAC 7M-SS (Stainless Steel) heavy-duty cold storage shelving system, paired with an integrated HVAC system, gave them a way to centralize their compounds in one place—and continue to stay competitive in their market.